How can Cimatron contribute to the manufacturing process?

Data import

|

Quoting

|

Parting

|

Preliminary design

|

Design

|

Drawing

|

Electrodes

|

NC programming

|

Data import | Quoting | Parting | Preliminary design | Design | Drawing | Electrodes | NC programming |

-

Data Import

Import your customer data and start working within seconds.

-

Quoting

Win more business with quick and accurate quoting.

-

Parting

Use QuickSplit, the industry’s fastest and most accurate parting and cavity design tool.

-

Preliminary Mold Design

Create quick preliminary 3D designs to evaluate strategies and gain customer approval.

-

Mold Base Design

Load an entire mold base plate set in just minutes using standard and user-defined catalog parts.

-

Core, Cavity, & Sliders

Leverage automation to complete design of the mold’s main components rapidly.

-

Catalog Parts

Work with a large selection of commercial catalogs.

-

Lifters Design

Use a dedicated, applicative tool for lifters to speed the design process.

-

Inserts Design

Use a dedicated, applicative tool for inserts to speed your design process.

-

Ejection Systems

Use dedicated, applicative tools for the ejection systems to boost your design process.

-

Cooling Systems Design

Use applicative tool for cooling channels design to boost your design process.

-

Conformal Cooling Design

Use applicative tools to design conformal cooling channels and dramatically reduce the injection cycle time by using additive manufacturing technologies.

-

Runners Design

Use a dedicated, applicative tool to design the runners quickly and easily.

-

Motion Analysis & Collision Detection

Validate your design with built-in measurement, analysis, and collision detection capabilities.

-

ECO Management

Effectively analyze, implement, verify, track, and manage engineering change orders (ECOs).

-

Drawings

Create and reuse drawing templates incorporating customer specifications.

-

Fast, Efficient Programming

Enjoy background toolpath calculations and parallel execution of procedures for better hardware use and significant time savings.

-

Built-In CAD Functionality

Take advantage of a full hybrid system that enables you to combine wireframe, surfaces, local open solid, and solid functions as part of the NC environment.

-

Efficient Roughing

Undertake quick and effective ultra-high volume milling on 3D stock shapes with Rough VoluMill.

-

High-Quality Finishing

Choose from a rich set of 3- to 5-axis-optimized machining strategies.

-

Full 5-Axis Capabilities for Mold Making

Reduce the need for electrodes with direct milling of narrow slots and tiny corner radiuses.

-

Plate Machining & Drilling

Achieve efficient and accurate machining of plates with powerful pocket or profile milling options and full drilling capabilities.

-

Advanced Micro Milling for Miniature, High-Precision Milling

Cimatron is a pioneer in the field of micro milling, offering dedicated micro-machining strategies to manufacture molds for very small, high precision parts cost-effectively.

-

Simulation & Post-Processor Support

View the cutting process and its results prior to machining with a color-coded display to help analyze the remaining material around the part.

-

NC Setup & Tool Table Reports

Generate NC setup and tool table reports automatically as you post process a program.

RD-Support offers Cimatron courses.

The lenght of each course is different. We offer courses in-house & at customers location. The courses are divided into 2 types; CAD & CAM.

If interested, feel free to contact RD-Support.

CAD courses

Basic CAD Design

2 day course

• 2d & 3D Modeling

• Design of machine vices in assemby mode. Insertion of standard components.

• Drawing the manufacture of the vice.

Quick Splite

1 day course

• Learn how Cimatron quickly splits the workpiece in main pull and side pull directions. The workpiece is split and split surfaces are assessed on the basis of angular analysis and slip directions

• The start of mold construction.

Flat modeling

2 day course

• Requires knowledge of Cimatron.

• The construction of a motorcycle hood via surfaces. The technique of wireframe and surface modeling with C2 / G2 conditions.

• Finishes with creating a solid.

• Cut into solids with surfaces.

Mold Design

2 day course (expandable)

• Must have taken the Quick split course

• The construction of 2 item form-box with side drawers, inserts, inlets, ejectors, cooling ducts. Catalog parts with plates, screens, plugs, etc. are used.

• Drawing with BOM.

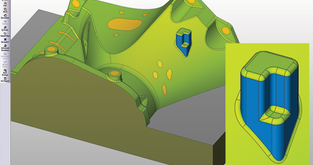

Electrode extraction

1 day course (expandable)

• Learn how Cimatron quickly pulls out electrodes both as solid or surface models.

• Set spark gap and 2D or 3D orbit ring.

• Create drawings for the setup on the EDM machine.

• Transfer variables to the NC and EDM setup.

CAM courses

Basic CAM - 3X milling

2 day course

• Get started with Cimatron CAM.

• Understand the parameters of scrubbing, medium and clear milling.

• Simulation with different methods.

• Postprocessing and NC report.

Advanced 3X milling

1 day course

• Get to know the advanced parameters. Both for scrubbing, medium and erasing.

• Learn to create "soft" paths that can hold the machine in the HSM area.

• Micro Milling.

AutoDrill

1 day course (expandable)

• Understand what AutoDrill can do. Traditional drilling, deep drilling, tearing, thread cutting, thread milling. Cooling hole drilling with gun drill and pocket milling. It's more than just drilling.

• Learn how to build your own template library for fully automatic hole drilling and pocket milling to optimize your hole drilling cycles.

• Can be driven both 3 & 5 axis.

4 & 5 axis production milling

2 day course

• 3 + 1 axis indexing on 4X cube. Fully Automatic Indexing 3 + 2 for scrubbing.

• Full 4X & 5X scrub.

• Intermediate scrub and erase with fully automatic 5X tilt. For the toolmaker who needs to go deep.

• 5X edge drive for deburring.

5 axis advanced surface milling

2 day course

• 5X driving in tracks and pipes.

• 5X edge and engraving.

• 5X scrub and erase in between guide folds.

• 5X machine simulation on the NC code.

Contact RD-Support via phone or mail

-

RD-Support’s Office

+45 2080 9980

-

Torkil Andersen

-

John Arvidsen