We have developed a new…

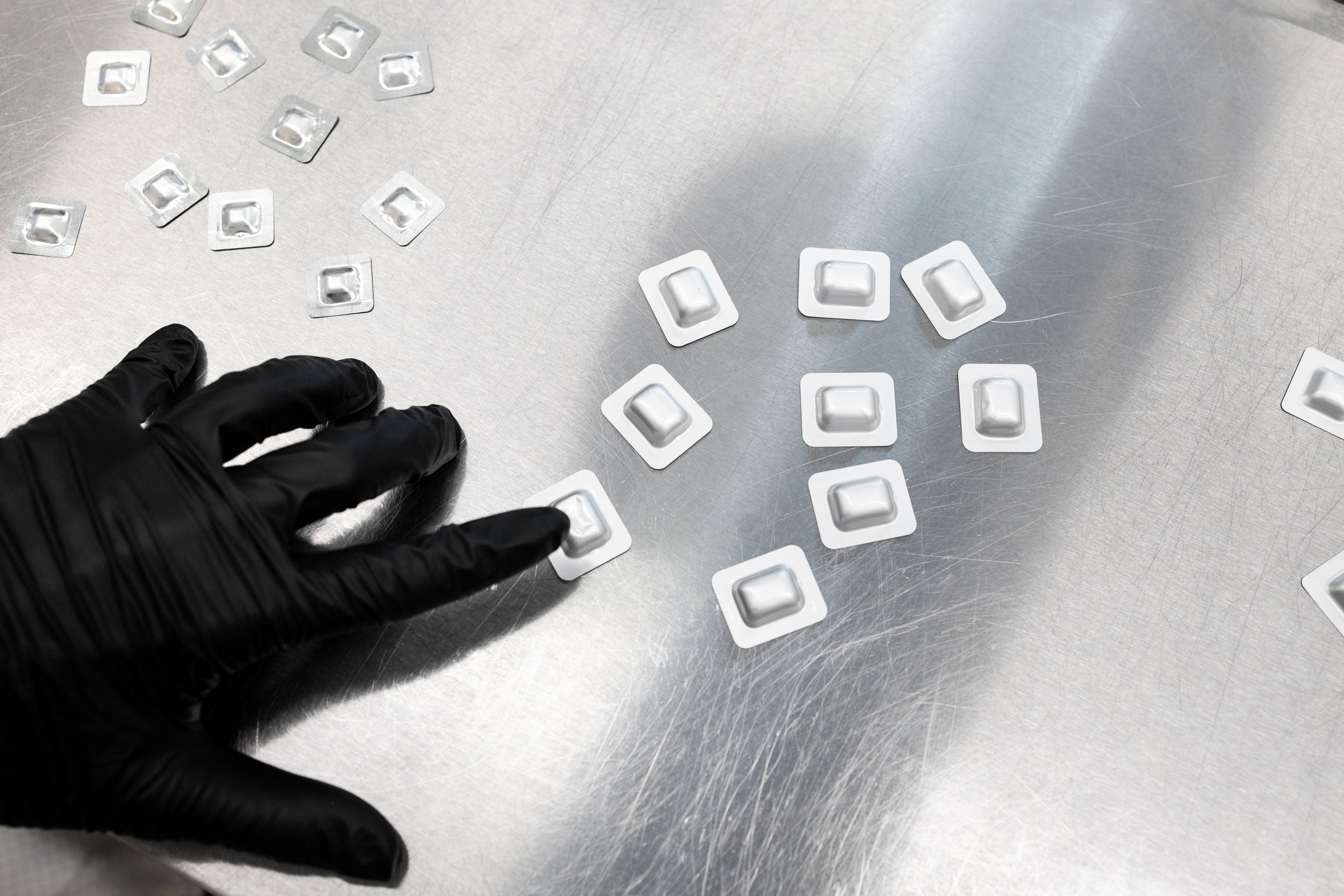

fully automated blister pouch machine

… with a unique dispense function that leaves your blisters with the exact volume required whether it is water, buffer or other liquids you will need in your blisters. The unique production method ensures the precise reagent filling to be 100% consistent and reproduceable.

Customize your shape and size, to the perfect fit on your microfluidic card.

The automated positioning of a puck ensures a precise pierce of the blister when placed on your microfluidic card.

Some of the benefits of our blisters buffer pouch include…

On-Chip Storage: Diagnostic reagents are stored directly on the microfluidic cartridge

Precise Reagent Dispensing: Only the microfluidic reagent volume required for the point-of-care test is stored

Simple Diagnostic Blister Activation: Dispensing can be controlled by mechanical compression of the reagent blister or post-release metering within the microfluidic cartridge

Prototype to Full-Scale Production: We offer both small and high-volume production solutions from the 100s to tens of millions.

Air-Free: 100% blister fill technology for zero headspace microfluidic reagent blisters that minimizes air from entering microfluidic channels

Low-Oxygen Reagents: Oxygen levels can be reduced to less than 2% using cutting edge vacuum filling technology

DNA/RNA Free: Complete DNA/RNA mitigation to avoid false positives for sensitive molecular diagnostic tests. Class VII and Class VIII cleanroom assembly

Turnkey Solution: Complete diagnostic consumable cartridge outsourcing including blister mounting, diagnostic cartridge contract manufacturing, and supply chain management